Explore the hidden life cycle of everyday products and their environmental impact, and learn how sustainable choices make a difference.

The Hidden Story Behind Everyday Products

Have you ever paused to think about how the objects around you came to be? The mug in your hand, the phone in your pocket, the shoes on your feet — each began as something entirely different. Behind every product lies a hidden story: one of raw materials drawn from the earth, shaped by design, transformed through manufacturing, transported across borders, used, and eventually discarded or reborn.

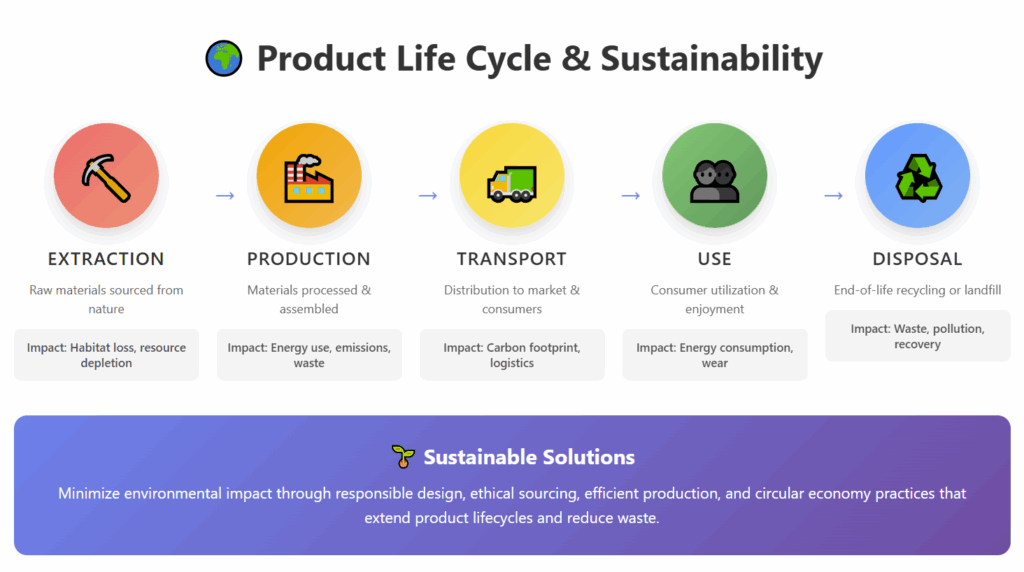

This journey is known as a product life cycle, a term that captures the complete lifespan of an item — from cradle to grave. It’s a story not just of creativity and convenience but of consequence. Every step along that path — extraction, production, transportation, and disposal — leaves a mark on the planet.

Understanding how a product is made isn’t merely a matter of curiosity; it’s a gateway to seeing how our daily choices ripple through ecosystems, economies, and communities. Each purchase is part of a far larger cycle, one that reveals both the brilliance of human innovation and the urgent need for sustainability in everything we create and consume.

Understanding the Product Life Cycle

Every product’s story unfolds through a series of interconnected stages, each with its own environmental footprint. It begins with raw material extraction — the mining, harvesting, or sourcing of the natural elements that form the product’s foundation. These resources then move into manufacturing, where design choices and industrial processes shape them into usable goods. From there, products are transported across supply chains, often spanning continents, before reaching the use phase, where consumers interact with them daily. Finally comes the end-of-life stage — a point that can lead to landfill, incineration, or, ideally, recycling and reuse.

To fully grasp the impact of this journey, scientists and sustainability experts rely on a method called Life Cycle Assessment (LCA). This analytical approach evaluates a product’s total environmental effect “from cradle to grave,” measuring everything from energy use and emissions to waste generation and resource depletion. It gives companies a map of where the most significant impacts occur — and where improvements will matter most.

By understanding these stages, both consumers and producers can make better decisions. Awareness of the product life cycle transforms the way we think about consumption — turning everyday choices into opportunities for change and accountability.

Design and Manufacturing: The Heart of Sustainability

If the product life cycle is a story, design and manufacturing are its opening chapters — and they determine much of how the story ends. The majority of a product’s environmental impact is “designed in” long before it ever reaches the shelf. Choices made in the design studio and factory floor — what materials to use, how efficiently to produce, how easily something can be repaired or recycled — define a product’s sustainability destiny.

Forward-thinking companies are now prioritising bio-based, recycled, and low-impact materials, replacing virgin plastics and metals with renewable alternatives. Manufacturing facilities powered by solar, wind, or other renewable energy sources are redefining what industrial responsibility looks like. These innovations not only reduce emissions and waste but also prove that profitability and sustainability can coexist.

As highlighted by experts in sustainable product development, the future lies in designing for longevity and circularity — creating goods meant to stay in use, not end up in the bin. From smarter production methods to re-engineered supply chains, innovation in manufacturing is steering us toward a world where making things responsibly becomes the norm, not the exception.

The Environmental Cost of Convenience

Plastic is perhaps the clearest example of how convenience comes with hidden consequences. In Emma Bryce’s TED-Ed video “What Really Happens to the Plastic You Throw Away”, the journey of three plastic bottles is traced — each taking a radically different path. One ends up in a landfill, where it can take up to a thousand years to decompose, leaching harmful chemicals into soil and groundwater. Another drifts into the ocean, breaking down into microplastics that infiltrate marine ecosystems and the human food chain. The third bottle, however, is successfully recycled, demonstrating how responsible handling can transform waste into a valuable resource.

This case study vividly shows that our everyday choices — even as simple as what we toss in the bin — have far-reaching environmental consequences. It’s a stark reminder that humans hold responsibility at every stage of a product’s life, from consumption to disposal, and that recycling systems and mindful waste management play a critical role in mitigating harm.

From Waste to Worth: The Circular Economy

The ultimate goal of sustainable manufacturing is to move beyond the traditional “take, make, dispose” model toward a circular economy, where materials are reused, repaired, or repurposed indefinitely. Circular strategies help reduce the demand for virgin raw materials, lower emissions, conserve energy, and minimise pollution.

Real-world examples of this approach abound. Sustainable product developers are designing items that are easier to recycle, repair, or extend in lifespan, ensuring that resources remain in use for as long as possible. From durable packaging to modular electronics, these initiatives demonstrate that products can be both functional and environmentally responsible.

By embracing circular design, businesses and consumers alike contribute to a more sustainable manufacturing future — one in which waste is minimised, value is preserved, and the environmental impact of production is thoughtfully managed.

Looking Ahead: Building a Sustainable Future

When we consider the full life cycle of a product, from raw material to disposal, it becomes clear that sustainability isn’t a single action — it’s a continuous process. Coupled with responsible manufacturing and circular economy principles, these insights create a blueprint for a future in which products serve both human needs and the planet.

Responsibility is shared. Producers can innovate by designing longer-lasting, recyclable, or repairable products, while consumers influence markets through mindful choices, recycling habits, and support for sustainable brands. Awareness and creativity together can transform industries, encouraging companies to rethink materials, energy use, and waste management.

Each product we purchase becomes an opportunity to participate in this transformation. By thinking critically about how items are made, used, and eventually disposed of, we contribute to a system that values longevity, efficiency, and ecological balance — moving toward a truly sustainable future.

Every stage of a product’s life — extraction, manufacturing, use, and disposal — carries environmental weight. By choosing thoughtfully, using responsibly, and disposing of products mindfully, we can reduce harm, extend value, and support a circular, sustainable economy. The story of every product is ultimately the story of our shared responsibility to tread lightly, innovate wisely, and live consciously.

Understanding how a product is made is more than a curiosity; it’s a reflection of our connection to the planet.

Note: All the images in this article were created using AI tools to help illustrate key ideas. We use these visuals to make the content more engaging and accessible while keeping the message clear and accurate.

Leave a Reply